Footing Design Software

Design of Strap footing

Introduction

When two columns are reasonably close, a combined footing is designed for both columns as shown in below. When two columns are far apart, a strap is designed to transfer eccentric moment between two columns as shown in below. The goal is to have uniform bearing pressure and to minimize differential settlement between columns.

ASDIP FOUNDATION is a structural engineering software utilized by engineers for design of pile caps and concrete footings, such as spread footings, strap footings, combined footings, and wall footings, per the latest ACI 318 provisions. STAAD Foundation Advanced analysis and design software addresses the building, plant, and tower industries by offering basic foundations such as isolated, combined, pile cap, and mat to specialized foundations including horizontal vessel foundations, tank annular ringwall, lateral analysis of pile/drilled pier, and state-of-the-art vibrational. Design phase – complete foundation designs per client specifications, provide necessary concrete/reinforcement details, include plot plan views and 3D models Construction phase – quickly determine an optimized solution after considering many what-if scenarios when things do not quite work out as planned. Overview SAFE is the ultimate tool for designing concrete floor and foundation systems. From framing layout to detail drawing production, SAFE integrates every aspect of the engineering design process in.

Design assumptions

- Strap does not provide bearing.

- Strap is ridge enough to transfer moment from one footing to the other.

Design procedure

Service load design:

- Determine the length of exterior footing and its eccentricity, e.

- Determine eccentric moment, M = Pa*e.

- Determine shear force, V = M / L

- Determine footing reaction, Ra = Pa+V, and Rb = Pb-V

- Determine footing sizes for both A & B.

Structural analysis

- Calculate factored column loads, Pua & Pub

- Calculate factored eccentric moment Mu = Pua*e

- Calculate factored shear, Vu = Mu / L

- Determine factored reactions, Rua & Rub.

- Perform structural analysis, determine factored shear and moment on footings and strap.

Reinforced concrete design

- Design exterior footing. Check shear stresses and design flexural reinforcement.

- Design interior footing. Check shear stresses and design flexural reinforcements.

- Design footing strap as a reinforced concrete beam.

Service load design:

Design procedure:

- Determine the length of exterior footing and its eccentricity, e.

- Determine eccentric moment, M = Pa*e.

- Determine shear force, V = M / L

- Determine footing reaction, Ra = Pa+V, and Rb = Pb-V

- Determine footing sizes for both A & B.

Determine sizes of strap footing

Given:

Column information:

Column A: Live load = 40 kips, Dead load = 50 kips

Column B: Live load = 80 kips, Dead load = 100 kips.

Distance between two columns: 22 ft.

Footing information:

Allowable soil bearing capacity; 3000 psf

Distance from column A to edge of footing: 1 ft.

Allowable soil bearing capacity = 3000 psf

Weight of soil above footing = 120 psf

Depth of footing= 24”

Depth of soil above footing = 12”

Requirements: Determine the size of footing A & B.

Solution:

Assume a footing width of 6 ft, the eccentricity of footing A is e = 6/2-1=2’.

The distance between footing reaction, L = 22-2=20’

The eccentric moment is M = (40+50)*2=180 ft-kips

The shear produced by M is, V = 180/20=9 kips

Reaction at footing A = 40+50+9 =99 kips

Net soil bearing capacity = 3000-2*150-120=2580 psf

Required footing area of A = 99/2.58=38.4 ft2.

Use 6’ by 6.5’ footing, area = 39 ft2.

Reaction at footing B = 100+80-9=171 kips

Required footing area = 171/2.58=66.3 ft2.

Use 8’ by 8.5’ footing, A = 68 ft2.

Structural analysis of strap footing

Procedures

- Calculate factored column loads, Pua & Pub

- Calculate factored eccentric moment Mu = Pua*e

- Calculate factored shear, Vu = Mu / L

- Determine factored reactions, Rua & Rub.

- Determine factored footing reactions.

- Perform structural analysis; determine factored shear and moment

on footings and strap.

Determine moment and shear in a strap footing

Given: The strap footing in

Requirement: Determine maximum factored shears and moment in the footings and strap.

Solution:

Factored column load of A = 1.4*50+1.7*40=138 kips

Factored column load of B = 1.4*100+1.7*80=276 kips

Factored eccentric moment, Mu = 138*2=276 ft-kips

Factored shear, Vu = 276/20=13.8 kips

Factored footing reaction at A = 138+13.8=151.8 kips

Concrete Pier Design Software

Factored footing pressure per linear foot of A = 151.8/6=25.3 k/ft

Factored footing reaction at B = 276-13.8=262.2 kips

Factored footing pressure per linear foot at B = 262.2/8=32.8 k/ft.

Shear diagram:

At point 1: Vu = 25.3*1.5-138= -100.1 kips

At point 2: Vu = 25.3*6-138=13.8 kips

At point 3: Vu = 25.3*6-138=13.8 kips

At point 4: Vu = 13.8+32.8*3.5= 128.6 kips

At point 5: Vu = 32.8*-3.5=-114.8 kips

Moment diagram:

At point 1: Mu = 25.3*1.52/2-138*0.5= -40.5 ft-kips

At point 2: Mu = 25.3*62/2-138*5= -234.6 ft-kips

At point 3: Mu = 25.3*6*(6/2+13)-138*(5+13)=-55.2 ft-kips

At point 4: Mu = 25.3*6*(6/2+13+3.5)-138*(5+13+3.5)+32.8*3.52/2=194 ft-kips

Strip Footing Design Software

At point 5: Mu = 32.8*3.52/2=200.9 ft-kips

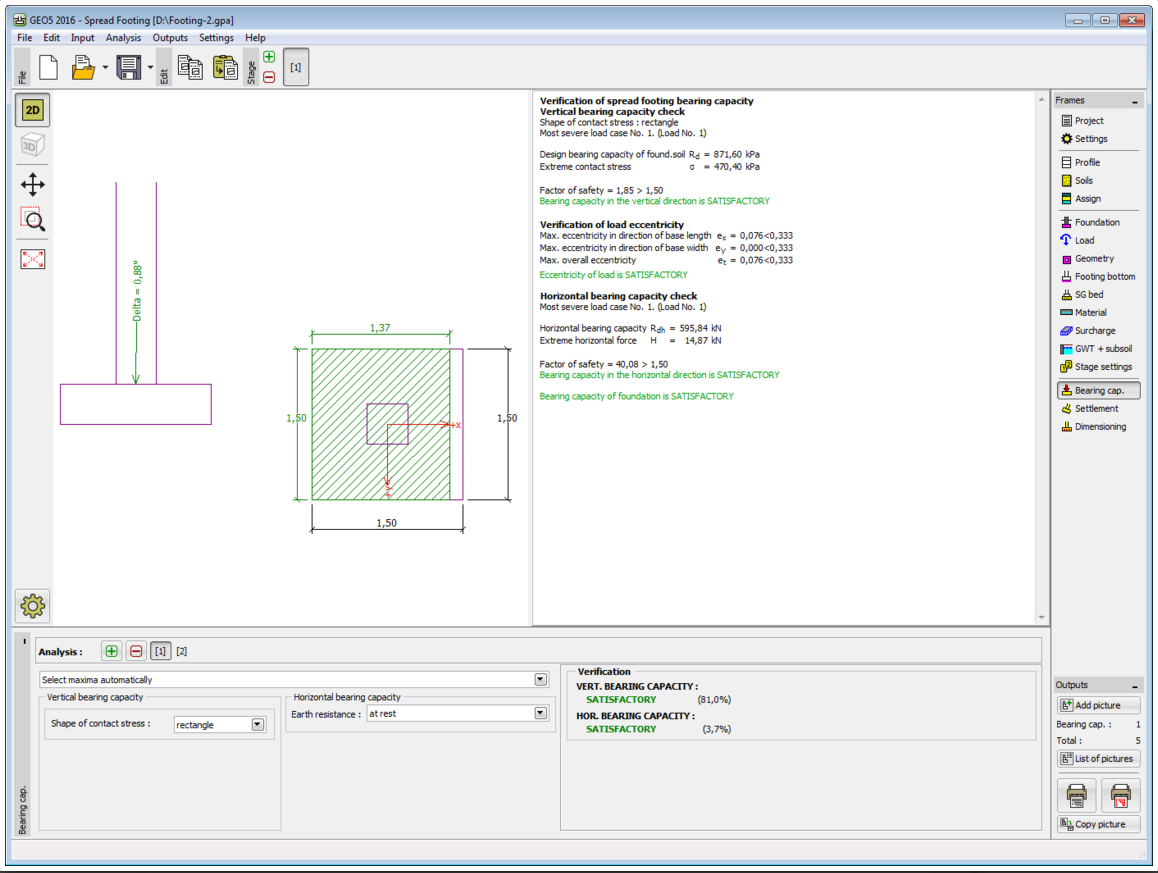

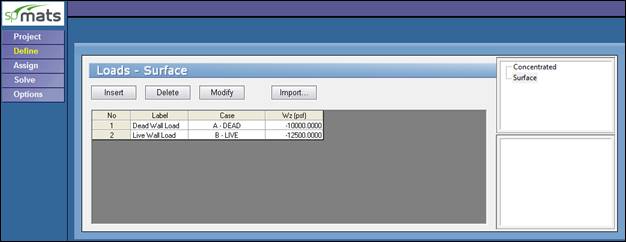

Spread Footing Design Software

Star trek armada 2000 download. Reinforced concrete design of strap footing

Design procedure:

- Design exterior footing. Check shear stresses and design flexural reinforcement.

- Design interior footing. Check shear stresses and design flexural reinforcements.

- Design footing strap as a reinforced concrete beam.